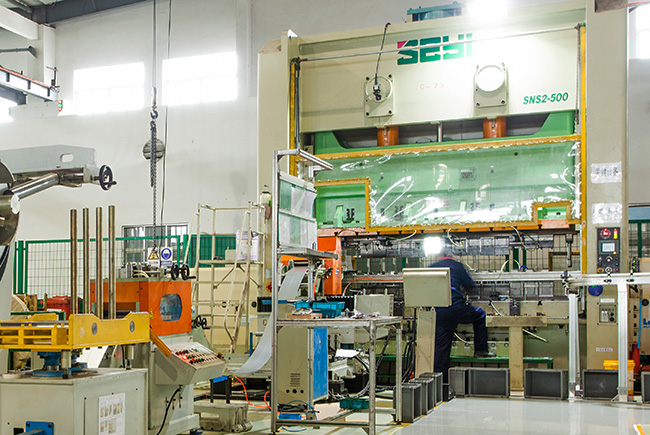

We have more than 50 sets of facilities ranging from 45-500 tons with progressive die and transferring die.It can realize the punching precision within 0.02mm and thedrawing forming precision within 0.05mm. The products are mainly used in the fields of security, automobiles, and electrical switches.

Progressive Workshop

Transferring Deepdrawing Workshop

The stamping equipment capacity of factory is 30T-200T, with a total of more than 20 sets, mainly high-speed punching presses, SPM: 80-400 times per minute.

Factory

Factory